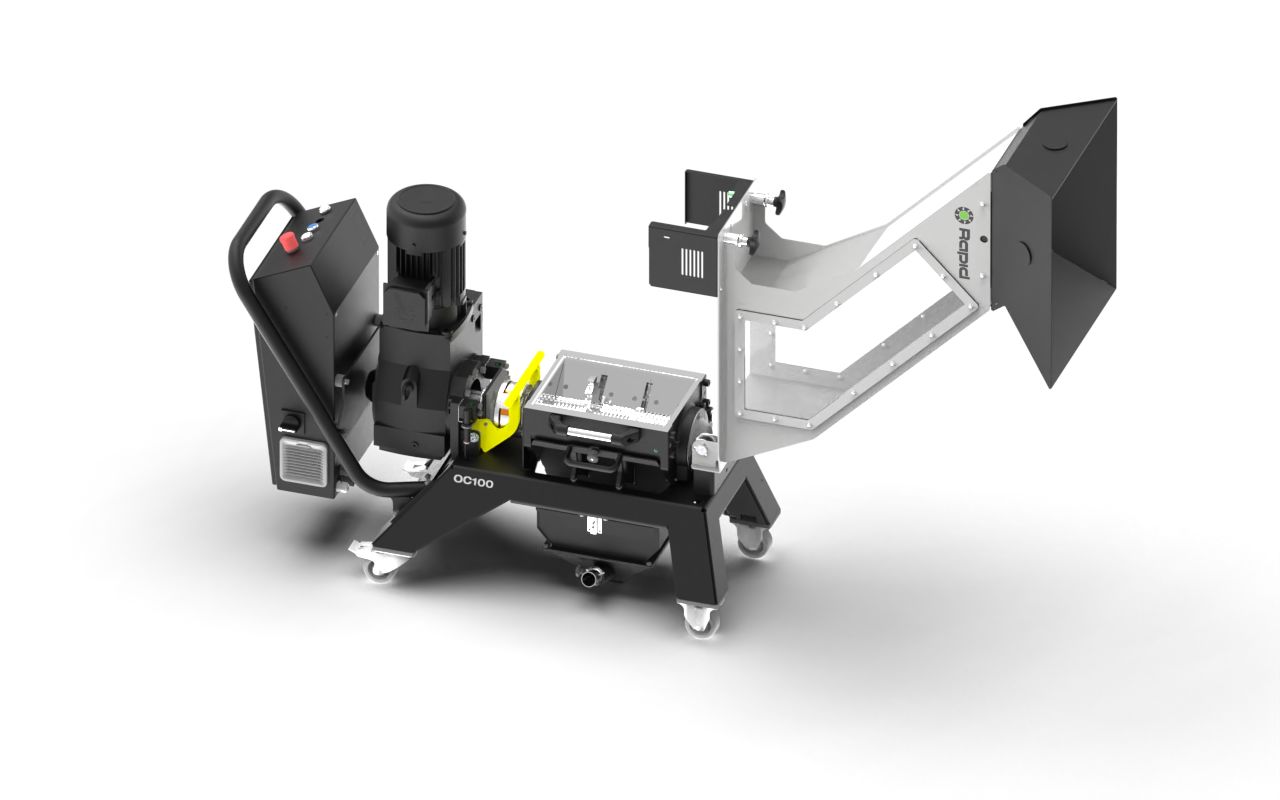

Rapid OneCUT PRO is an efficient slow-speed granulator, suitable for grinding of smaller products, sprues, etc. It is available with several innovative features. These are just a few of the benefits of OneCUT PRO. Add smart metal detection and low noise levels, and it becomes the obvious standard for slow-speed granulators.

Granulators

OneCUT PRO

-

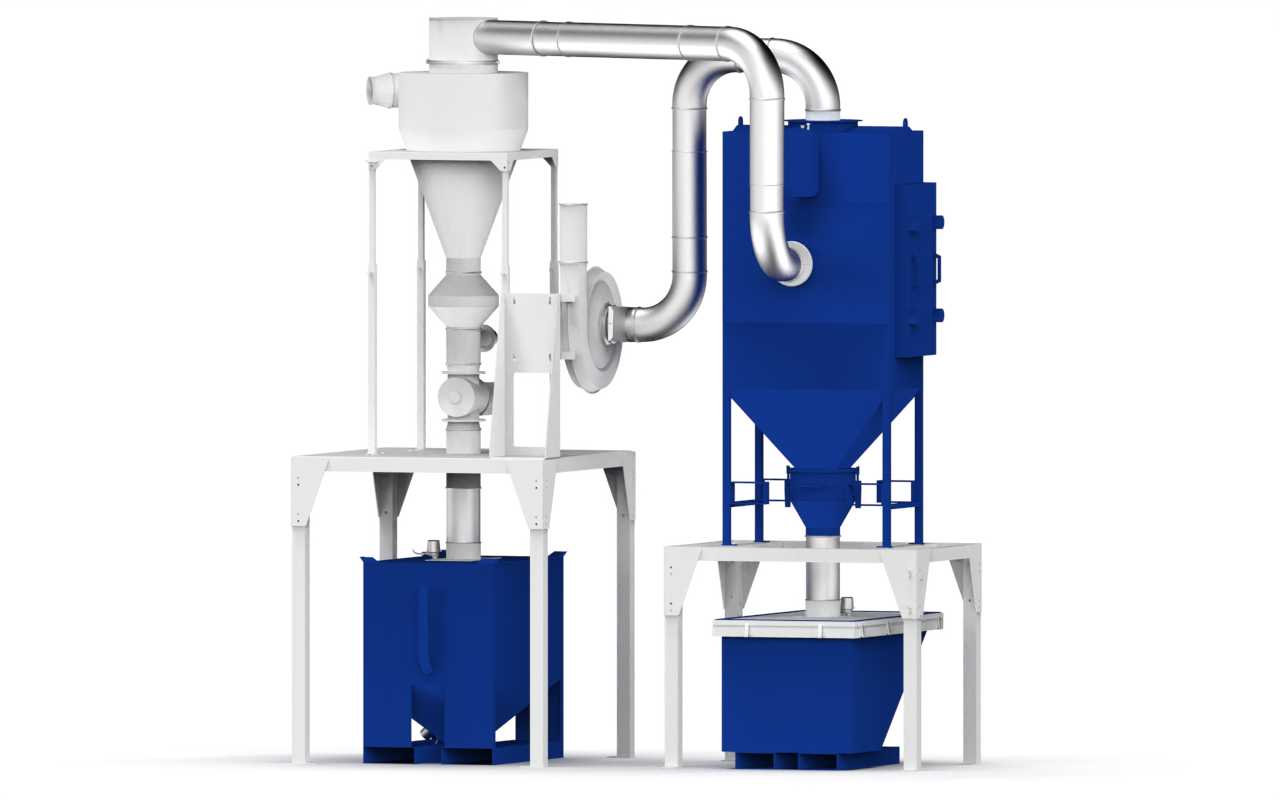

Rapid EnergySMART

- Utilize the granulator overcapacity to save significant amount of the energy cost. With Rapid Stop&Go mode the granulator can stop and restart in intervals. During pause mode, you’ll have zero energy consumption and no noise. After a user preset time the granulator starts again and recycles all the accumulated material in the hopper and then it stops again.

-

Turnable knives and hooks

- The Rapid OneCUT PRO is designed for minimal cost of ownership. The main wear and tear parts, like the fixed knives and the cutting hooks, are turnable for double life time.

-

PowerTECH execution

- The OneCUT PRO can also be delivered in a PowerTECH execution for very abrasive materials. With PowerTech execution the rotating-, fixed- and scraper knives have a super hard treatment for maximum wear resistance.

-

Automatic rotor reversal

- Automatically reversing rotor if material has blocked the rotor, stirring up and releasing material in cutter house.

-

NEW Rapid Metal Detection (RMD)

- Stop rotor instantly, prevents costly damage, and keeps downtime minimal (Optional).

Rapid OneCUT PRO is an efficient slow-speed granulator, suitable for grinding of smaller products, sprues, etc. It is available with several innovative features. These are just a few of the benefits of OneCUT PRO. Add smart metal detection and low noise levels, and it becomes the obvious standard for slow-speed granulators.

FlexiSPEED – Optimize and save energy

With the potentiometer on the panel, you can easily change the rotor speed ± by 40% (15-35 rpm) to get the best regrind quality for every granulation run.

Lower speeds – for brittle materials, lower noise levels and lower energy consumption.

Higher speeds – suitable for soft materials or when higher capacity is required.

Rapid QRR (Quick Rotor Release)

Thanks to Rapid QRR, the OneCUT can be opened completely to access the granulator housing and disconnect the rotor in about 30 sec. Quick and easy access to clean or for service and maintenance. A freely rotating rotor and full visibility of the cutterhouse means that you do not have to guess whether the granulator is clean or not.

The opening / closing of the cutterhouse is facilitated by a gas spring, which makes it easy to open and safe to close the heavy granulator housing.

Straight cut with offset segments

The straight rows of knives maximize the gripping of sprues and products. Properly gripped material enables efficient cutting and reduces dust and fine particles that affect the process negatively.

The "teeth" are square to give a uniform high-quality regrind, and the rotor segments are staggered, which gives a smoother cut and lower energy consumption.

Specifications

| Model | 100-22 | 100-33 | 100-44 | |

| Rotor | ||||

| Rotating knives | 1 | 2 | 3 | |

| Rotor segments | 2 | 3 | 4 | |

| Cutterhouse | ||||

| Fixed knives | 2 | 3 | 4 | |

| Scrapers | 2 | 3 | 4 | |

| Size | mm | 215x220 | 330x220 | 445x220 |

| Transmission | ||||

| Motor standard | kW | 1.5 | 1.5 | 1.5 |

| Motor alternatives | kW | 2.2 | 2.2 | 2.2 |

| Model | 100-22 | 100-33 | 100-44 | |

| Rotor | ||||

| Rotating knives | 1 | 2 | 3 | |

| Rotor segments | 2 | 3 | 4 | |

| Cutterhouse | ||||

| Fixed knives | 2 | 3 | 4 | |

| Scrapers | 2 | 3 | 4 | |

| Size | inch | 8.5"x8.5" | 13"x8.5" | 17.5"x8.5" |

| Transmission | ||||

| Motor standard | HP | 2 | 2 | 2 |

| Motor alternatives | HP | 3 | 3 | 3 |

Media & Video

Dimensional drawing/layout

| OneCUT PRO | 100-22 | 100-33 | 100-44 |

| A | 215 | 330 | 445 |

| B | 200 | 260 | 320 |

| C | 520 | 605 | 690 |

| D | 1160 | 1280 | 1400 |

| E | 1720 | 1800 | 1890 |

| OneCUT PRO | 100-22 | 100-33 | 100-44 |

| A | 8.5" | 13" | 17.5" |

| B | 7.9" | 10,2 | 12.5" |

| C | 20.5" | 23.8" | 27.2" |

| D | 45.7" | 50.4" | 55" |

| E | 67.7" | 70.9" | 74.5" |