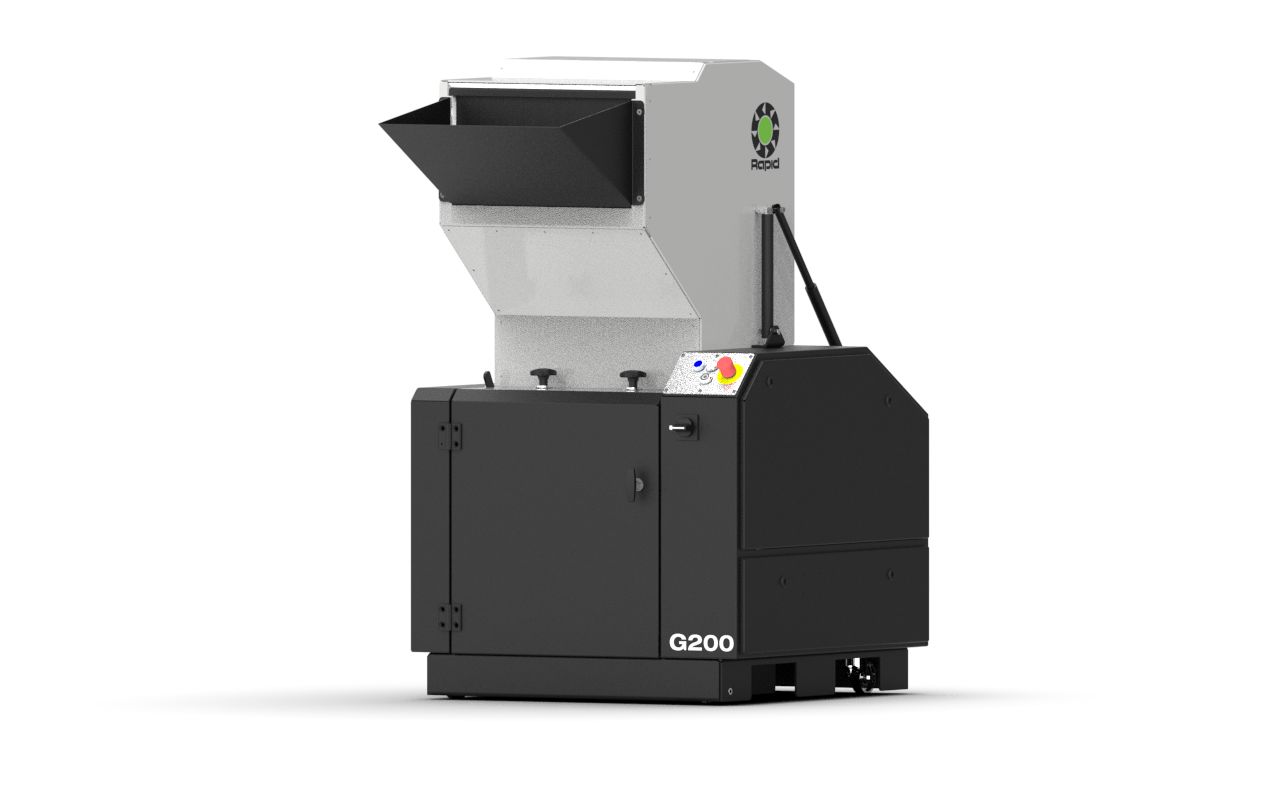

The models in the Rapid 200 series are ideal for direct recycling of sprues and reject products, especially from injection molding and blow molding machines.

Thanks to various customizing options such as different cutterhouses, rotor configurations, rotor speeds, etc., we can offer a granulator that can be adapted to your specific requirements.

Regardless of your production conditions, we have a 200 series model that will suit your specific needs.

Granulators

200 Series

-

Low energy consumption

- The 200 Series is offered in three different rotor speeds, 260, 400 or 840 rpm, assuring the most effective configuration related to the application. Choosing the optimal rotor speed minimizes energy consumption.

-

High quality regrind

- The Rapid cutting technique, comprised of clean scissors-cutting action and constant cutting circle, produces granules of a uniform size with minimal dust content even with the toughest materials.

-

Compact and flexible

- Compact and flexible with several types of infeeds, including manual feeding, belts, roller feeds etc.

-

Constant Cutting Circle (CCC)

- Rapid granulators and shredders deliver precise, consistent cuts every time. This design ensures even wear, improved efficiency, and reduced energy consumption, making our machines durable, reliable, and ideal for heavy-duty applications.

The models in the Rapid 200 series are ideal for direct recycling of sprues and reject products, especially from injection molding and blow molding machines.

Thanks to various customizing options such as different cutterhouses, rotor configurations, rotor speeds, etc., we can offer a granulator that can be adapted to your specific requirements.

Regardless of your production conditions, we have a 200 series model that will suit your specific needs.

Cutterhouse

Depending on what is granulated, it is important to choose the right cutterhouse to get optimal grip and sufficient capacity. The Super-tangential version provides optimal grip for voluminous lighter products such as jars, bottles and other relatively thin-walled products. Tangential cutterhouse is available as an alternative for more compact and thick-walled products.

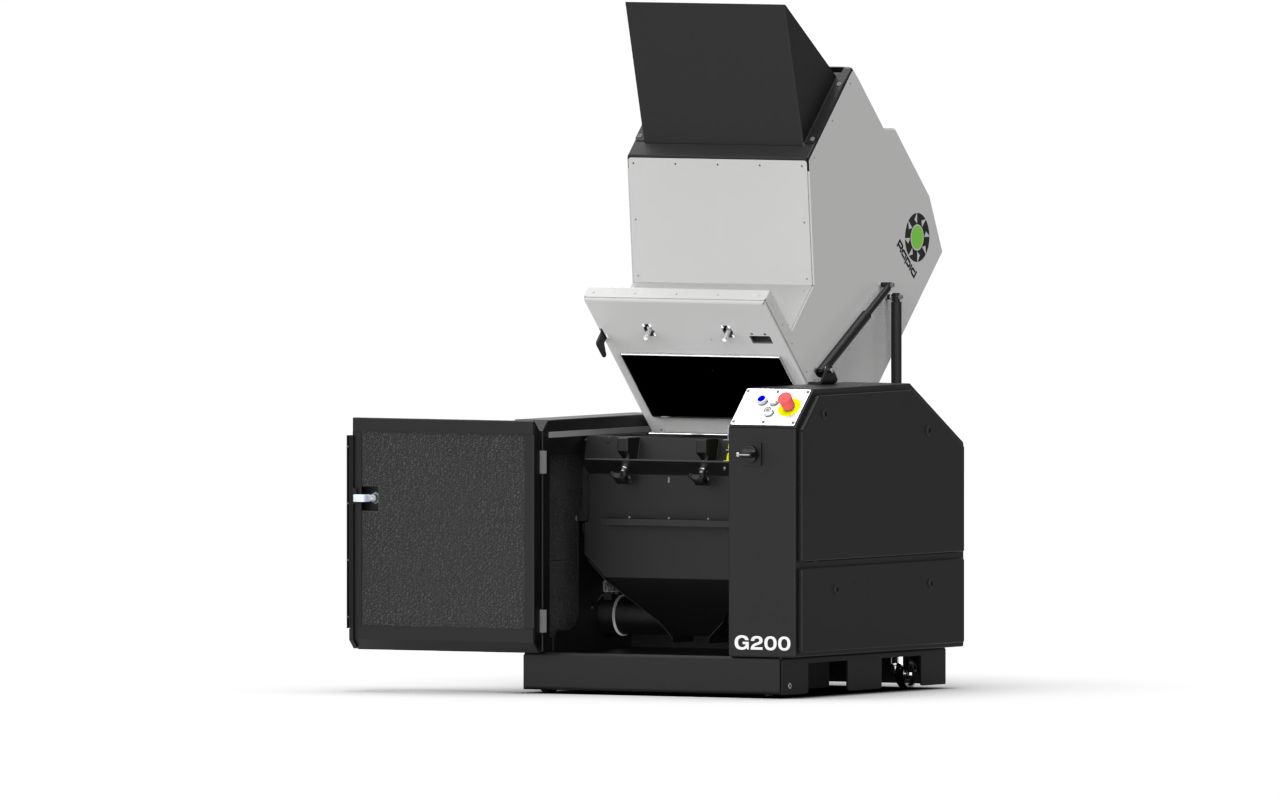

Rotors

The Rapid 200 series is available with 2 different rotor types, "open" with pre-adjustable blades or “staggered” with small offset cassette blades located in rotor segments. Both types give the best possible granules and are easy to change.

Reversible Screen

Most granulation or cutting occurs at the screen surface. Hence it is extremely important to have the screen in good condition. A worn screen gets rounded hole edges and needs to be replaced with a new screen. Screens from Rapid are reversible (excluding special screens) which gives them double the life.

Specifications

| Model | 200-24 | 200-36 | 200-48 | 200-60 |

| Rotor | ||||

| Rotor diameter, (mm) | 200 | |||

| Rotor, type | Staggered | |||

| Rotor alternative, optional | 3 blade open rotor | |||

| Rotating knives | 6 (3 x 2) | 9 (3 x 3) | 12 (3 x 4) | 15 (3 x 5) |

| Cutterhouse | ||||

| Super-Tangential, dim (mm) | 240 x 230 | 360 x 230 | 480 x 230 | 600 x 230 |

| Fixed knives | 2 | 2 | 2 | 2 |

| Transmission | ||||

| Motor, standard (kW) | 4.0 | 5.5 | 5.5 | 5.5 |

| Optional motor alternatives, (kW) | 5.5, 7.5, 11 | 7.5, 11 | 7.5, 11 | 7.5, 11 |

| Screen | ||||

| Screen hole diam., (mm) | 6 | 6 | 6 | 6 |

| Screen, alternative hole diam., (mm) | 4 - 5 - 8 - 10 - 12 | |||

| Hopper | ||||

| Standard hopper inlet, (mm) | 240 x 200 | 360 x 200 | 480 x 200 | 600 x 200 |

| Model | 200-24 | 200-36 | 200-48 | 200-60 |

| Rotor | ||||

| Rotor diameter, (Inch) | 8" | |||

| Rotor, type | Staggered | |||

| Rotor alternative, optional | 3 blade open rotor | |||

| Rotating knives | 6 (3 x 2) | 9 (3 x 3) | 12 (3 x 4) | 15 (3 x 5) |

| Cutterhouse | ||||

| Super-Tangential, dim (Inch) | 8" x 10" | 8" x 14" | 8" x 19" | 8" x 24" |

| Fixed knives | 2 | 2 | 2 | 2 |

| Transmission | ||||

| Motor, standard (Hp) | 5 | 7.5 | 7.5 | 7.5 |

| Optional motor alternatives, (Hp) | 7.5 - 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 |

| Screen | ||||

| Screen hole diam., (Inch) | 1/4" | |||

| Screen, alternative hole diam., (Inch) | 3/16” - 5/16” - 3/8” - 1/2” | |||

| Hopper | ||||

| Standard hopper inlet, (Inch) | 9 1/2 x 8” | 14 x 8” | 19 x 8” | 24 x 8” |

Media & Video

Dimensional drawing/layout

| Model | 200-24 | 200-36 | 200-48 | 200-60 |

| A | 650 | 770 | 890 | 1100 |

| B | 240 | 360 | 480 | 600 |

| Model | 200-24 | 200-36 | 200-48 | 200-60 |

| A | 9 7/16" | 14 3/16" | 18 3/16" | 23 5/8" |

| B | 26 3/4" | 31 1/2" | 36 1/4" | 40 15/16" |