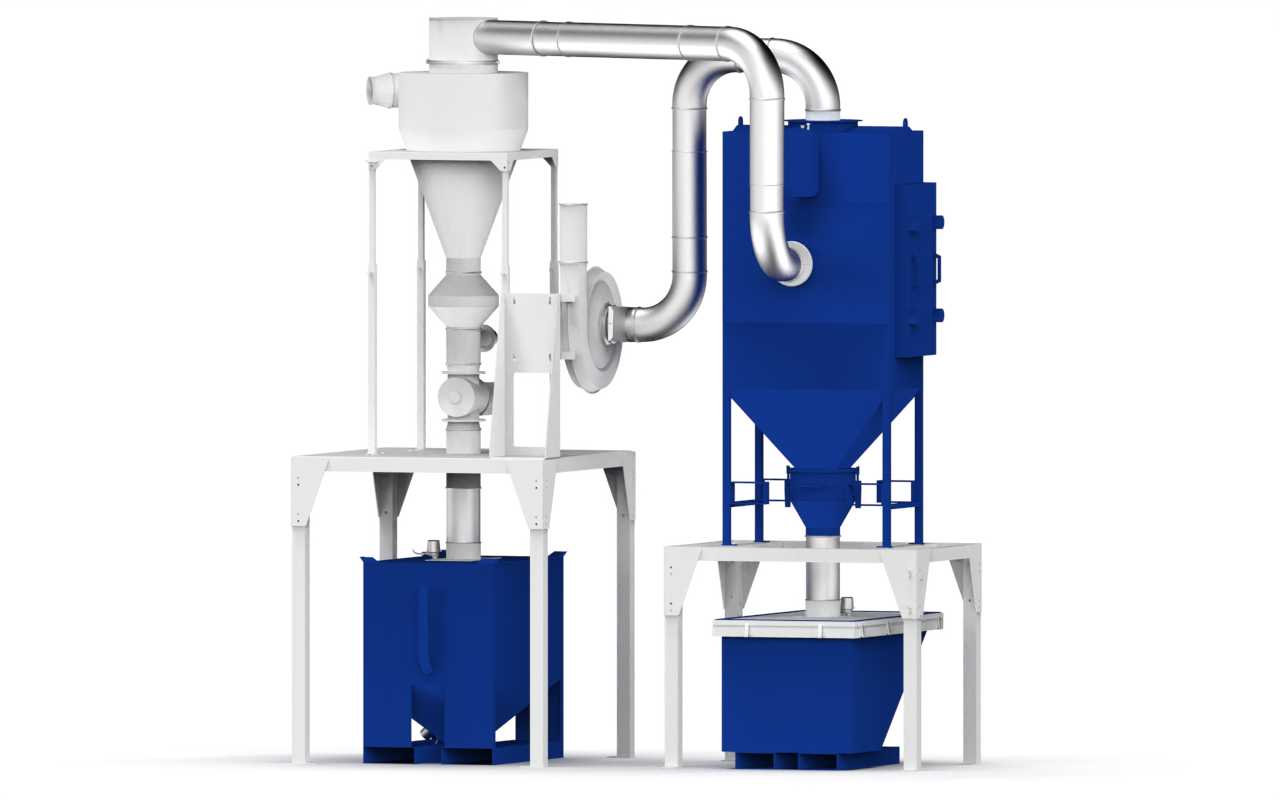

Raptor FlexiPUSH shredders are designed for all types of thermoplastics, large 1200-liter IBC containers or lumps - everything is ground down efficiently. Rapid Raptor shredders come in 2 widths, 800 and 1350 mm. The standard version is equipped with FlexiPUSH (pneumatic pusher). The machine can also be equipped with a TopPUSH, a function that presses the material against the rotor to improve output capacity. It is specially developed for bulky products.

3 rotor variants – film/foil, lump, bulky material.

Shredders

Raptor FlexiPUSH

-

Screens if needed

- The Raptor shredders run fine without screens, but screens with different hole sizes are available. As in Rapid’s large granulators, the screens are split in two to ease handling. The turnable screens are unbolted and unwelded making them very easy to remove when cleaning and servicing.

-

Heavy duty transmission

- The heavy duty design of the gear box makes it reliable, energy efficient and at the same time quiet. It’s belt driven for efficient operation.

-

MCT – mineral composite filled base for reduced vibrations

- The Raptor-Series’ base can be made of a special mineral composite material to give extra stability, reducing vibrations even in the toughest applications.

Raptor FlexiPUSH shredders are designed for all types of thermoplastics, large 1200-liter IBC containers or lumps - everything is ground down efficiently. Rapid Raptor shredders come in 2 widths, 800 and 1350 mm. The standard version is equipped with FlexiPUSH (pneumatic pusher). The machine can also be equipped with a TopPUSH, a function that presses the material against the rotor to improve output capacity. It is specially developed for bulky products.

3 rotor variants – film/foil, lump, bulky material.

Open-Hearted Design

Offers total access to the interior of the shredder, including granule box and screen. This provides unmatched access to both rotating and fixed knives for service and maintenance.

Allows visibly clean inspection with easy and complete view of cleaning surfaces to ensure no residual or hidden material thereby preventing contamination at color changes.

Pusher System

FlexiPUSH – pneumatically driven pusher for simpler applications with lower capacity requirements. The pusher design allows a completely closed feed that effectively prevents leakage.

The FlexiPUSH shredders can also be supplemented with TopPUSH to compress bulky and voluminous products, for example – IBC, 200-liter drums, etc.

Raptor Industry 4.0

All Raptors come with a programmable PLC-control that enables monitoring and remote communication. The machine has a built-in WiFi supporting real time tracking of the recycling process, energy usage, warning messages about possible problems and much more.

"Recipes" can be changed and created for each recycled material to optimize for capacity and energy usage in line with your requirements.

Specifications

| Model | FLEXIPUSH 800 | FLEXIPUSH 1350 |

| Rotor | ||

| Rotor diameter, (mm) | 280 | 280 |

| Rotating knives | 23 | 39 |

| Rotor speed (rpm) | 60 | |

| Cutterhouse | ||

| Cutterhouse dimensions (mm) | 800x1010 | 1350x1010 |

| Fixed knives | 3 | 5 |

| Transmission | ||

| Motor, standard (kW) | 11 | 22 |

| Optional motor alternatives, (kW) | 15, 18.5, 22, 30, 37, 45 | 15, 18.5, 22, 30, 37, 45 |

| Screen | Optional | Optional |

| Screen hole diam., (mm) | 16-75 | 16-75 |

| Hopper | ||

| Standrad hopper inlet, (mm) | 800x1350 | 1350x1350 |

| Weight, (kg) | 4200 | 5000 |

| Model | FLEXIPUSH 800 | FLEXIPUSH 1350 |

| Rotor | ||

| Rotor diameter, (inch) | 11" | 11" |

| Rotating knives | 23 | 39 |

| Rotor speed (rpm) | 60 | 60 |

| Cutterhouse | ||

| Cutterhouse dimensions (inch) | 31.5"x38" | 31.5"x38" |

| Fixed knives | 3 | 5 |

| Transmission | ||

| Motor, standard (Hp) | 15 | 30 |

| Optional motor alternatives, (Hp) | 20, 25, 30, 40, 50, 60 | 20, 25, 40, 50, 60 |

| Screen | Optional | Optional |

| Screen, hole diam., (inch) | 5/8"-3 | 5/8"-3 |

| Hopper | ||

| Standrad hopper inlet, (inch) | 31.5"x53" | 31.5"x53" |

| Weight, (Ibs) | 9300 | 11000 |

Dimensional drawing/layout

| Model | FLEXIPUSH 800 | FLEXIPUSH 1350 |

| A | 800 | 1350 |

| B | 520 | 1070 |

| C | 1730 | 2280 |

| Model | FLEXIPUSH 800 | FLEXIPUSH 1350 |

| A | 31.5" | 53" |

| B | 20.5" | 42" |

| C | 68" | 90" |