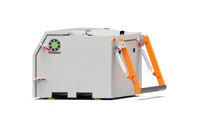

Rapid 300-LBB (Low Built Base) has a very low infeed height. The areas of use are primarily in the packaging industry for granulating skeletal waste and sheet. The granulator can either be connected in-line to the production machine with a roll-feeder and loop control or placed under the line with a simple funnel for freely falling cut waste sheets. Available in 3 widths, 900, 1200 and 1500 mm.

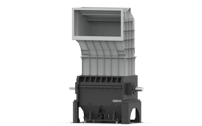

Granulators

300 LBB

-

High quality regrind

- The Rapid cutting technique, comprised of clean scissors-cutting action and constant cutting circle, produces granules of a uniform size with minimal dust content even with the toughest materials.

-

Constant Cutting Circle (CCC)

- Rapid granulators and shredders deliver precise, consistent cuts every time. This design ensures even wear, improved efficiency, and reduced energy consumption, making our machines durable, reliable, and ideal for heavy-duty applications.

Rapid 300-LBB (Low Built Base) has a very low infeed height. The areas of use are primarily in the packaging industry for granulating skeletal waste and sheet. The granulator can either be connected in-line to the production machine with a roll-feeder and loop control or placed under the line with a simple funnel for freely falling cut waste sheets. Available in 3 widths, 900, 1200 and 1500 mm.

Low Infeed

The low-built 300-LBB granulator, featured above includes a roll feeder and loop control located directly under a thermoforming line. The skeletal waste is granulated and fed directly back to the process. Startup waste in the form of full and/or unpunched sheet can also be granulated without any modifications to the machine.

Specifications

| Model | LBB 300-90 | LBB 300-120 | LBB 300-150 |

| Rotor | |||

| Rotor diameter, (mm) | 300 | 300 | 300 |

| Rotating knives | 6 (2 x 3) | 8 (4 x 2) | 10 (5 x 2) |

| Cutterhouse | |||

| Fixed knives | 6 | 6 | 9 |

| Transmission | |||

| Motor, standard (kW) | 7.5 | 11 | 11 |

| Optional motor alternatives (kW) | 7.5, 11, 15, 18.5, 22, 30 | ||

| Screen | |||

| Screen hole diam., (mm) | 8 | 8 | 8 |

| Weight | |||

| Weight, (kg) | 1200 | 1350 | 1500 |

| Model | LBB 300-90 | LBB 300-120 | LBB 300-150 |

| Rotor | |||

| Rotor diameter, (inch) | 12" | 12" | 12" |

| Rotating knives | 6 (2 x 3) | 8 (4 x 2) | 10 (5 x 2) |

| Cutterhouse | |||

| Fixed knives | 6 | 6 | 9 |

| Transmission | |||

| Motor, standard (Hp) | 10 | 15 | 15 |

| Optional motor alternatives (Hp) | 10, 15, 20, 25, 30, 40 | ||

| Screen | |||

| Sreen hole diam., (inch) | 5/16" | 5/16" | 5/16" |

| Weight | |||

| Weight, (lbs) | 2650 | 3000 | 3300 |