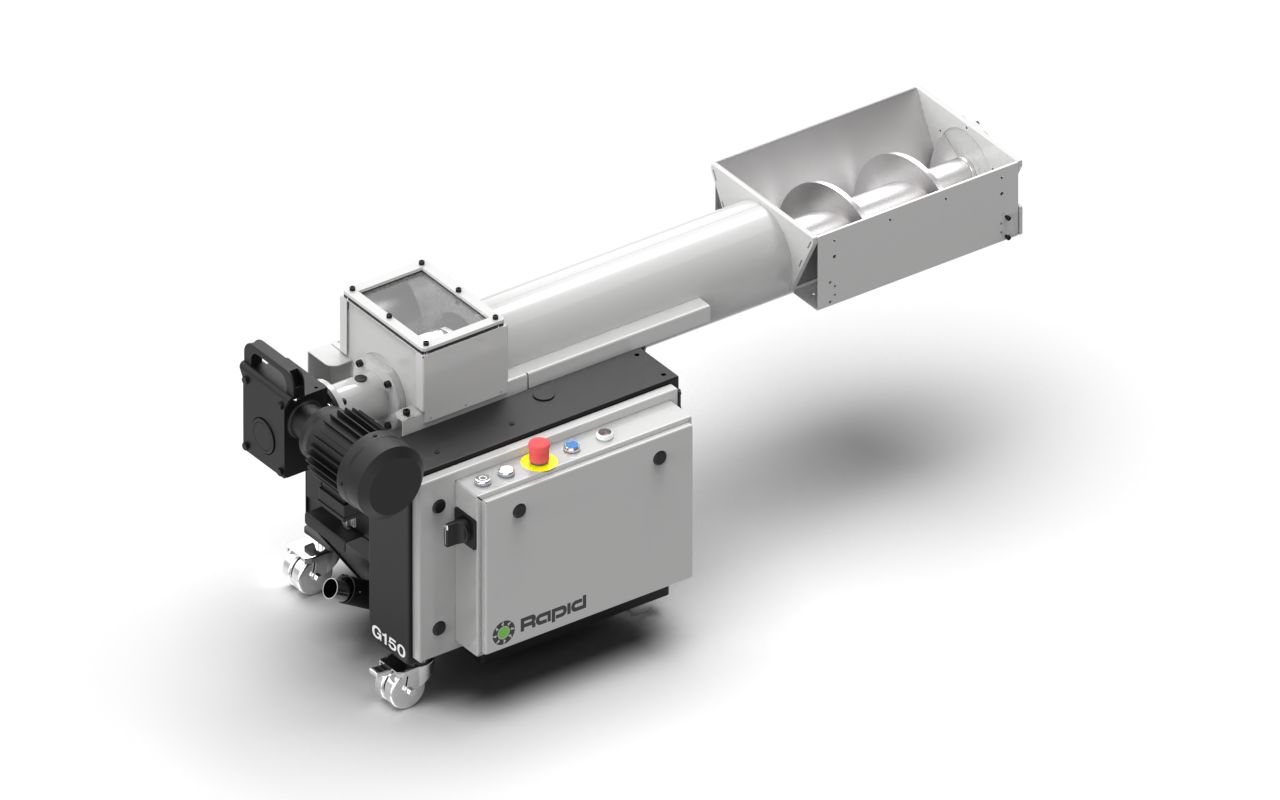

Rapid 150 series is a small high-performance granulator that is primarily intended for "beside the press" recycling of sprues and defective small products. Immediate grinding directly at the production machine allows the regrind to be returned directly to the process. It raises the product quality and avoids accumulation of sprues and reject products.

Granulators

150 Series

-

DeltaTECH – standard models with flexibility

- Rapid 150 DeltaTech is the most dynamic product line within the 150-Series. With 7 different models and a wide range of standard options, each model can be tailormade to each application.

-

PowerTECH – configured for filled/abrasive materials

- The PowerTech line is specifically developed for filled and abrasive materials. It is optimized for long lasting wear resistance and top quality regrind, No compromises!

-

Constant Cutting Circle (CCC)

- Rapid granulators and shredders deliver precise, consistent cuts every time. This design ensures even wear, improved efficiency, and reduced energy consumption, making our machines durable, reliable, and ideal for heavy-duty applications.

Rapid 150 series is a small high-performance granulator that is primarily intended for "beside the press" recycling of sprues and defective small products. Immediate grinding directly at the production machine allows the regrind to be returned directly to the process. It raises the product quality and avoids accumulation of sprues and reject products.

Recycled material with properties of virgin resin

Knives of the highest quality and Rapid's unique knife placement that maintains a constant distance between the screen and the housing, help produce regrind with properties equivalent to virgin raw material. You can feed the granulated material directly back into the process without any intermediate storage, drying, etc.

The goal of all recycling is to get a regrind that has uniform size distribution with minimal dust & fine particles. Rapid's 150 series fully supports "Closed Loop Operation" for best production yield.

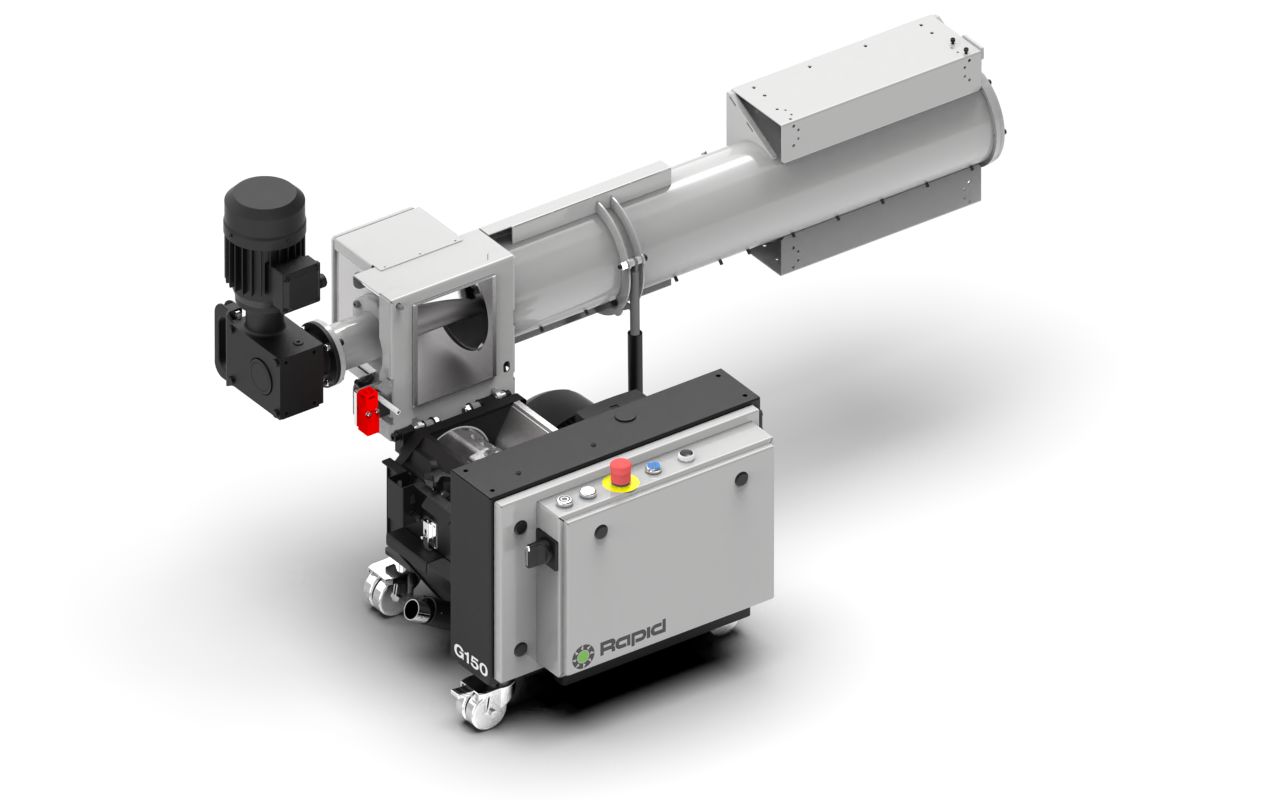

Easy cleaning

Easy cleaning and easy maintenance is fundamental demands for Rapid 150-Series. Instant access to all components provides easy cleaning when changing e.g. material or colours.

Staggered cassette knives

Staggered and angled placement of knives on the rotor allows more cuts per revolution. More cuts in turn produces a much smoother and energy-efficient granulation that results in a regrind with smooth edges and melting properties equivalent to virgin raw material.

Special manufacturing process and use of high-quality steel help ensure the small cassette knives have a very long service life. And when it is time to change knives, it's a quick and hassle-free process.

Specifications

| Model | 150-21 | 150-35 | 150-42 |

| Rotor diameter, (mm) | 150 | 150 | 150 |

| Rotor type | Staggered | Staggered | Staggered |

| Rotating knives | 9 (3 x 3) | 15 (5 x 3) | 18 (6 x 3) |

| Cutterhouse, dim (mm) | 210 x 150 | 350 x 150 | 420 x 150 |

| Fixed knives | 2 | 2 | 2 |

| Motor, standard (kW) | 2.2 | 2.2 | 2.2 |

| Motor, alternative, (kW) | 4.0 | 4.0 | 4.0 |

| Screen hole diam. (mm) | 5 | 5 | 5 |

| Infeed opening, (mm) | 210 x 150 | 345 x 150 | 415 x 150 |

| Weight, (kg) | 160 | 200 | 220 |

| Model | 150-21 | 150-35 | 150-42 |

| Rotor diameter, (inch) | 6" | 6" | 6" |

| Rotor type | Staggered | Staggered | Staggered |

| Rotating knives | 9 (3 x 3) | 15 (5 x 3) | 18 (6 x 3) |

| Cutterhouse, dim (inch) | 6" x 9" | 6" x 14" | 6" x 17" |

| Fixed knives | 2 | 2 | 2 |

| Motor, standard (HP) | 3 | 3 | 3 |

| Motor, alternative, (HP) | 5 | 5 | 5 |

| Screen hole diam. (inch) | 3/16" | 3/16" | 3/16" |

| Infeed opening, (inch) | 6" x 9" | 13 1/2" x 9" | 16 5/16" x 9" |

| Weight, (lbs) | 350 | 440 | 500 |

Media & Video

Dimensional drawing/layout

| Model | 150-21 | 150-35 | 150-42 |

| A | 490 | 630 | 700 |

| B | 270 | 340 | 375 |

| C | 500 | 640 | 710 |

| D | 490 | 630 | 700 |

| Model | 150-21 | 150-35 | 150-42 |

| A | 19.29" | 24.80" | 27.56" |

| B | 10.60" | 13.39" | 14.76" |

| C | 19.69" | 25.20" | 27.95" |

| D | 19.29 | 24.80" | 27.56" |