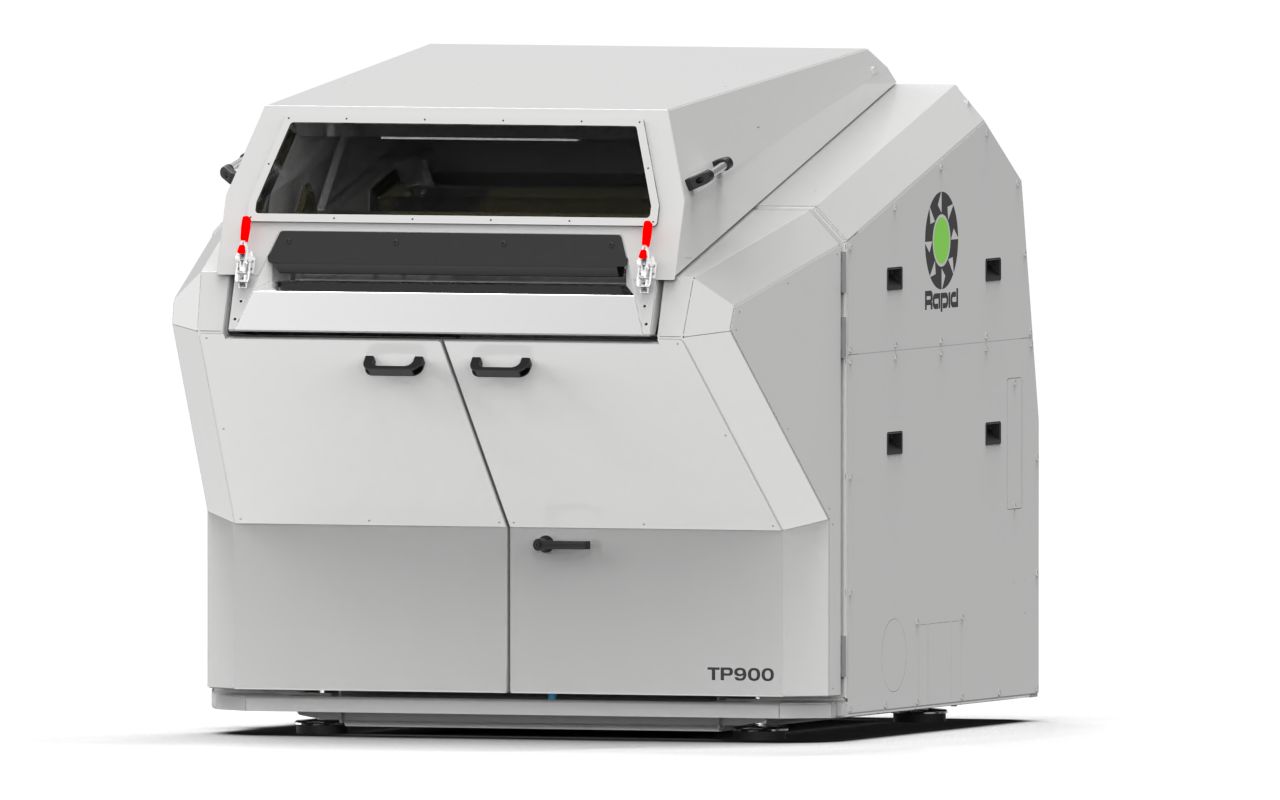

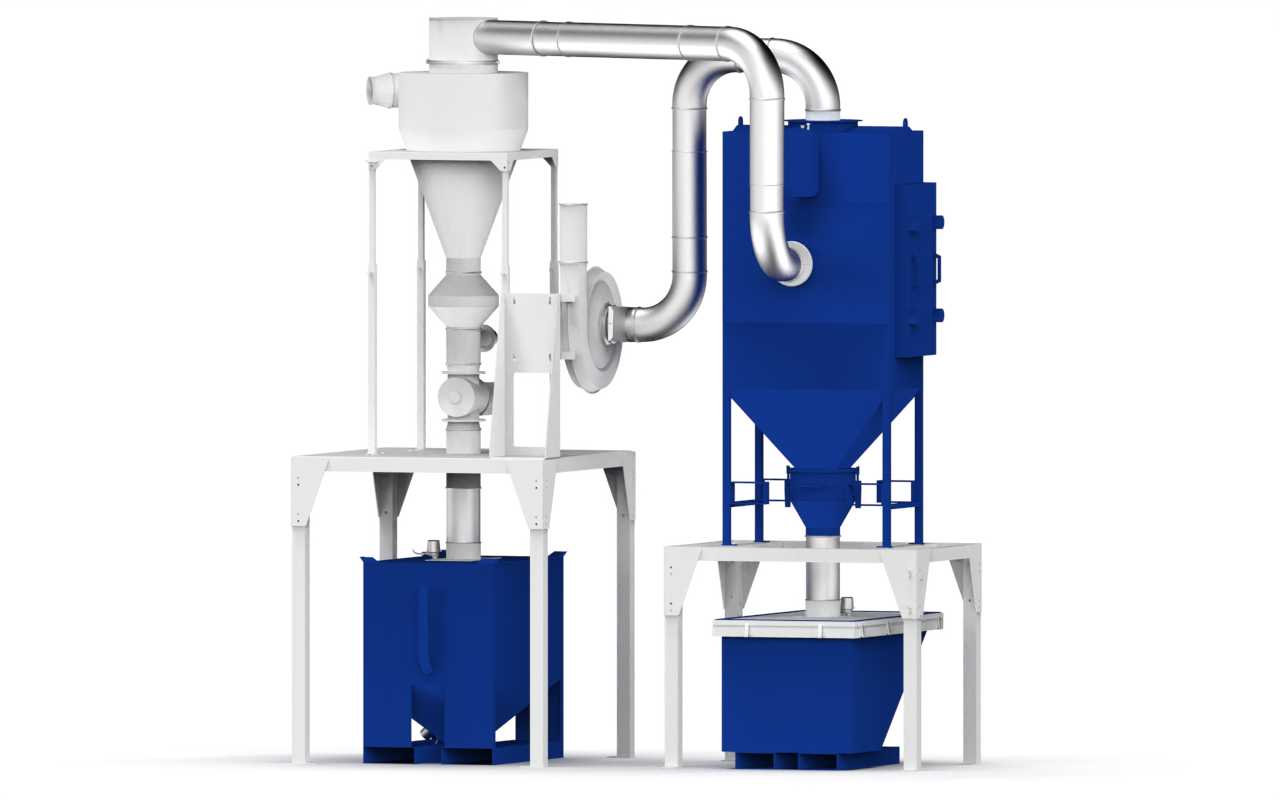

Rapid ThermoPRO for low noise granulation of skeletal waste. Available in 3 widths, 600, 900 and 1200 mm.

Granulators

ThermoPRO

-

Open-Hearted design

- Rapid's Open-Hearted design provides quick, easy and complete access to the granulator’s heart – the cutting area of the granulator. This facilitates quick and easy cleaning when changing colors or materials. Maximum visibility of the cutting area removes doubts if it is clean or not with no hidden corners where materials can be "missed". Replacement of knives are also easy due to the easy access.

-

3 types of loop control

- 3 types of loop control – fully integrated, external or free-standing loop control for in-line integration with the thermoforming machine.

-

The market's lowest noise level

- With complete sound enclosure for below 80 dB (A), depending on material and application.

-

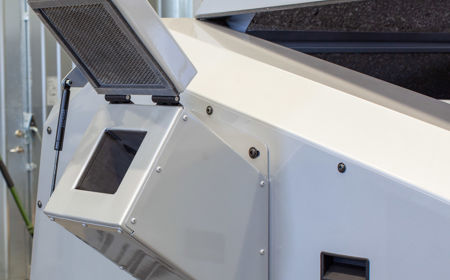

Inspection window with lights

- A very safe and simplified solution for operator to monitor operation and when starting up the feeding of granulator.

-

MCT – mineral composite base for reduced vibrations

- The Raptor-Series’ base can be made of a special mineral composite material to give extra stability, reducing vibrations even in the toughest applications.

-

Constant Cutting Circle (CCC)

- Rapid granulators and shredders deliver precise, consistent cuts every time. This design ensures even wear, improved efficiency, and reduced energy consumption, making our machines durable, reliable, and ideal for heavy-duty applications.

Rapid ThermoPRO for low noise granulation of skeletal waste. Available in 3 widths, 600, 900 and 1200 mm.

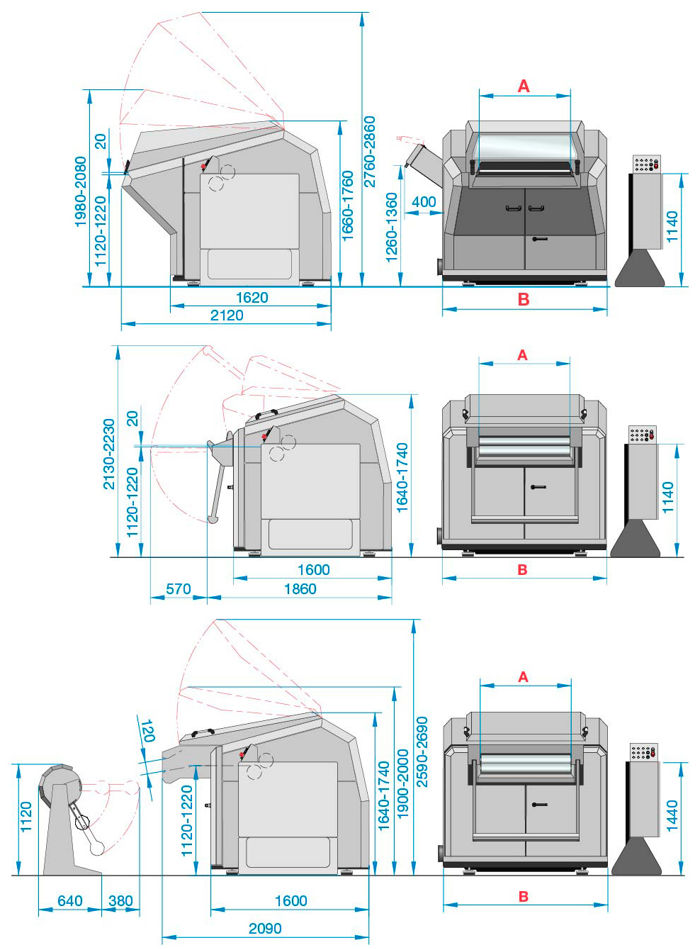

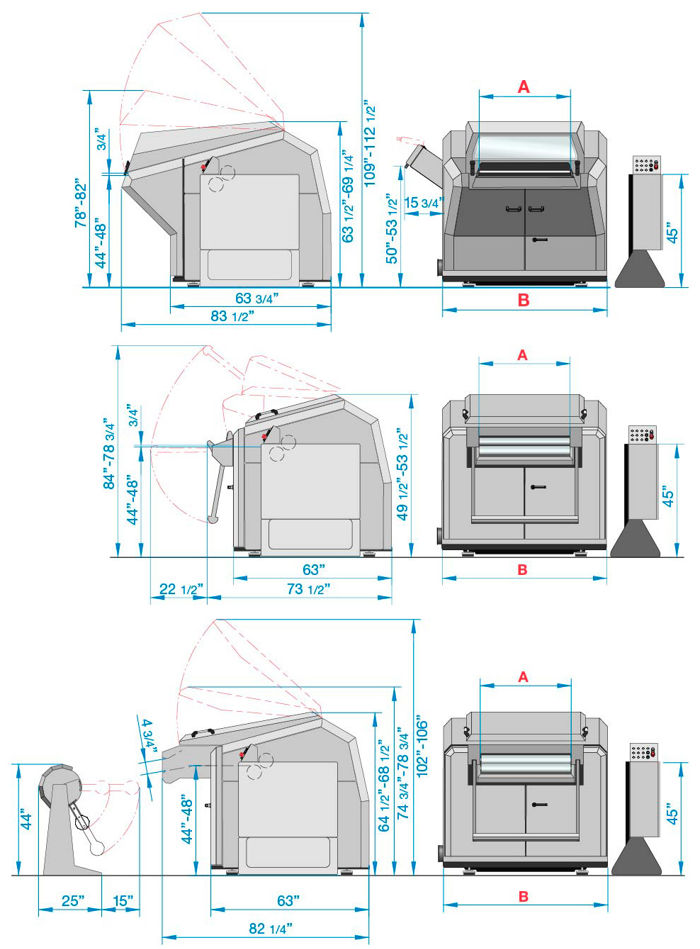

Integrated loop control

With integrated loop control the noise level is reduced to below 80 dB (A) in most applications. The machine is equipped with an inspection window for the operator to easily detect issues with feeding.

External loop control

Suitable for in-line granulation of skeletal waste with unpunched products. Can handle up to 80 mm mold depth depending on material.

The loop control arm is mounted in front of the machine and is removable to facilitate service and cleaning of the machine. It can be supplemented with weights for improved functionality.

Stand-alone loop control

Suitable for deep-draw products of up to 200 mm and when there is unpunched products in the skeleton. The loop arm can be supplemented with weights for improved functionality.

Specifications

| Model | 400-60 | 400-90 | 400-120 |

| Rotor, diameter (mm) | 350 | ||

| Rotor type | 3 blade, open | ||

| Rotating knives | 3 | 3 | 2x3 |

| Fixed knives | 2 | 2 | 2x2 |

| Cutterhouse, Tangential (mm) | 620 x 360 | 920 x 360 | 1220 x 360 |

| Motor, Standard (kW) | 11 | 15 | 22 |

| Motor, alternatives (kW) | 11 / 15 / 18,5 / 22 / 32 / 37 | ||

| Model | 400-60 | 400-90 | 400-120 |

| Rotor, diameter (inch) | 13 3/4" | ||

| Rotor type | 3 blade, open | ||

| Rotating knives | 3 | 3 | 2x3 |

| Fixed knives | 2 | 2 | 2x2 |

| Cutterhouse, Tangential (inch) | 24" x 14" | 36" x 14" | 48" x 14" |

| Motor, Standard (HP) | 15 | 20 | 30 |

| Motor, alternatives (HP) | 11 / 15 / 18,5 / 22 / 32 / 37 | ||

Media & Video

Dimensional drawing/layout

| ThermoPRO 600 | ThermoPRO 900 | ThermoPRO 1200 | |

| A | 620 | 920 | 1220 |

| B | 1360 | 1660 | 1960 |

| ThermoPRO 600 | ThermoPRO 900 | ThermoPRO 1200 | |

| A | 24" | 36" | 48" |

| B | 53 1/2" | 65 1/2" | 77" |